Cone Silencers

Typical Fan Connections

Bolted To Fan:

Lower fan-silencer energy loss

Break-out noise minimized with flexible connector located at silencer discharge

More mass for improved vibration isolation efficiency

Blind bolting is standard (add-on for raised flange)

Direct Duct Connection:

Potential noise break-out problem when flexible connector is attached to fan discharge

Up to 50% more energy loss, unless costly center-body extension is specified to match fan motor or impeller hub circumference

Slight reduction in silencer cost

Increased Acoustic Performance Options

The ratings listed are based on a standard silencer length equivalent to one fan diameter.

Improved attenuation can be obtained from Models CS-1.5, 2.0, 3.0 or intermediate lengths, within system space limitations and/or acoustic requirements.

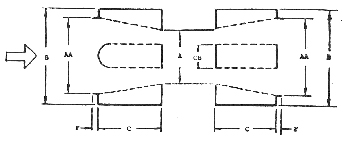

(Model CSI)(Model CSD)

A … Fan Diameter

AA … Duct or plenum connection diameter

B … Overall silencer casing diameter

C … Acoustic length (silencer overall length C + F)

CB … Center-body diameter

F … Flange or slip allowance (2" unless otherwise specified)

| Typical Designation | ||||

|---|---|---|---|---|

| 54 | CS | I or D | – 1 – | CB26 |

| Fan Diameter | Axial Cone Silencer | Intake or Discharge | Nominal Length One Fan Diameter | Center-Body Diameter |

Standard Construction

Up to 30" Fan Diameter … 22ga Galvenized Lockform Casing

… 28ga Galvenized Perforated Liner30" to 48" Fan Diameter … 22ga Casing/28ga Liner or

… 16ga Casing/22ga LinerAbove 48" Fan Diameter … 16ga HRS Welded Casing, 22ga Galvenized Perforated Liner

All sizes employ 3lb density fiberglass acoustic media, erosion protected by FG cloth.

Heavier gauges than standard, special materials or paint finishes are available on request.

If silencer is to be duct connected, length of center-body extension to minimize energy losses must be specified. (e.g. for a 10" increase in CB length, silencer designation becomes 54CS( )-1-CB26-10)