Alphaloc Panels

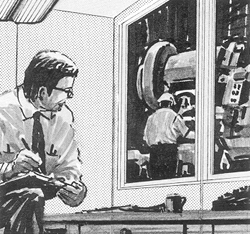

Personnel Enclosures - prefabricated or custom panels may be applied to establish "quiet areas" within harsh, acoustical environments.

Custom/OEM Enclosures - these systems reflect an optimum design to balance cost and performance for volume production.

Test Chambers - high performance acoustical doors, windows and panels are ideally suited to both new construction or upgrading of existing test facilities.

Aerodynamic/Thermodynamic Acoustics - the reduction of airborne noise, while maintaining the desired airflow and heat transfer may be achieved with acoustically treated air foils and turning vanes.

Process Machine Enclosures - ASI Aeroacoustic designs process noise abatement systems with product logistic and accessability in mind.

Engineered Solutions for Noise

Fabricate custom walls, barriers and enclosures from pre-fabricated panel modules. Modular construction makes the project quick, economical and effective.

Light weight, high performance panel modules are ideally suited for use in walls, barriers and enclosures. Direct interchangeability of each module permits rapid assembly into rugged structures. Generic flexibility allows user to swiftly and easily alter or expand the configuration to meet changing needs. Two people using ordinary hand tools can assemble a complete system in a matter of hours. Variety of options will adapt the basic structure to meet environmental requirements and material logistics.

Features

-

Simple, rapid assembly with ordinary hand tools

-

Each panel is independently accessible without disturbing the adjoining sections

-

Total interchangeability of panel module permits alterations to enclosure layout without degrading acoustical performance

-

Fully demountable

-

Durable, light interior finish

-

Full exterior priming

-

All assembly hardware supplied - nothing else to buy

-

Single glazed, acoustically-sealed windows

-

May be skid-mounted for portability

Options

-

Complete factory assembly

-

Forced ventilation and/or air conditioning

-

Lighting

-

Electrical wiring and/or plumbing

-

Weather proofing

-

Acoustical floor

-

Vibration isolation (available with floor option)

-

Custom finishes

-

Double leaf doors

-

Acoustical labyrinths and ports

-

Speech designs for custom applications

-

Disposable air filters

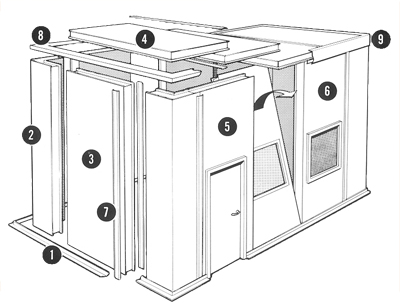

- Base angle - when secured to floor, provides attachment and positive acoustical seal for panel buttons.

- Corner module - seamless corners minimize noise leaks and adds structural rigidity to the system.

- Wall panel - standard panel module being utilized as wall section.

- Ceiling panel - standard panel module forming a ceiling section.

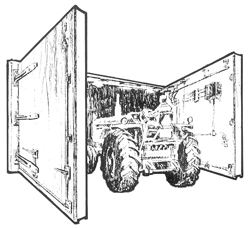

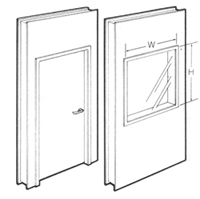

- Door module - interchangeable with standard panel module but includes a complete, preinstalled acoustical door and seals.

- Window module - directly interchangeable with standard panel module but contains a factory installed and acoustically-sealed window assembly.

- Panel connector - provides an acoustically-sealed structural joint between panels and decorative appearance.

- Panel cap - covers panel lip and provides structural alignment of panel tops.

- Ceiling trim - provides an additional acoustical seal and decorative facade.

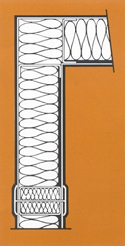

Floor and ceiling

attachments provide

excellent acoustical

sealing and structural

rigidity. The floor

mounting angle may be

located inside or outside

the enclosure. All

attachment connectors

provide a smooth and

clear appearance to both

the interior and exterior

of the structure.

A reinforced, seamless

corner assures acoustical

integrity while adding

overall rigidity of the

structure. Our unique

approach to the

interconnection of each

module permits individual

access to all elements

for placement or structural

modification.

The window module may

be specified in lieu of a

standard panel. Each

window module is

available in either single

or double glazing,

consistent with the

performance criteria for

the enclosure. Although

the window assembly

is factory sealed, each

pane is removable for

cleaning or replacement.

The door module is

totally interchangeable

with standard panel

modules. Each door

module is furnished

complete with the

acoustical jambs, seals

and safety latches. The

entire assembly is as

easily installed as a

panel module.

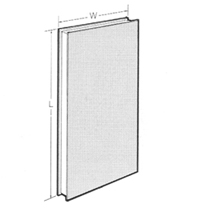

| Panel Modules | |||||||

|---|---|---|---|---|---|---|---|

| Widths (W) | Lengths (L) |  |

|||||

| 8 Ft. | 10 Ft. | 12 Ft. | 14 Ft. | 16 Ft. | |||

| 2 Ft. | P28 | P28 | P28 | P28 | P28 | ||

| 3 Ft. | P38 | P38 | P38 | P38 | P38 | ||

| 4 Ft. | P48 | P48 | P48 | P48 | P48 | ||

Example:

A 3′(W) × 16′ L) standard panel module – P316

A 4′(W) × 14′(L) standard panel module with acoustical vent –P414V

Other lengths and widths available upon request.

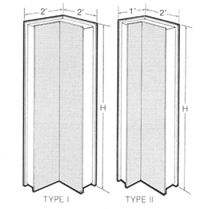

| Corner Modules | ||||||

|---|---|---|---|---|---|---|

| Lengths (L) |  |

|||||

| 8 Ft. | 10 Ft. | 12 Ft. | 14 Ft. | 16 Ft. | ||

| Type I (2 ft. × 2 ft.) |

C18 | C110 | C112 | C114 | C116 | |

| Type II (1 ft. × 2 ft.) |

C28 | C210 | C212 | C214 | C216 | |

Example:

A Type I corner module 8′ high(H) – C18

A Type II corner module 12′ high(H) – C212

To make a 90° panel joint without a corner section, please specify Corner Joint in the applicable height.

Other lengths and widths available upon request.

| Door and Window Panels | ||||||

|---|---|---|---|---|---|---|

| Widths (W) | Lengths (L) |  |

||||

| 1 Ft. | 2 Ft. | 3 Ft. | 4 Ft. | 5 Ft. | ||

| 1 Ft.* | W11 | W12 | W13 | |||

| 2 Ft.** | W21 | W22 | W23 | W24 | W25 | |

| 3 Ft.*** | W31 | W32 | W33 | W34 | W35 | |

Single Glaze Safety Glass (no suffix)

Double Glaze Safety Glass (DG suffix)

* For P2, P3, P4 panel series and door modules

** For P3, P4 Panel series and door modules

*** For P4 Series Panel only

Example:

A 3′(W) × 7′(H) window assembled in a 4′(W) × 14′(L) standard panel – P414 – W33

A 2′(W) × 4′(H) double glazed window assembled in a 3′(W) × 10′(L) standard panel – P310 – W24DG

Note: Window pane center line is 4′ 6″

A door module may be specified by adding a “D” suffix to a standard panel module.

“D” suffix for P4 Module Only.

A 3′(W) &time; 7′(H) door is standard

Example:

Standard 3′(W) × 7′(H) door assembled in a 4′(W) × 16′(L) panel – P416D

Standard 3′(W) × 7′(H) door with single glaze 1′ square window in a 4′(W) × 8′(L) panel – P48D – W11

Note: Window pane center line is 4′ 6″

For other door sizes or double leaf configuration, contact factory.

High performance jambs, seals and doors quoted upon request.

Panel modules are 4" thick and are framed with 14 gauge, galvannealed steel channel. One side is 14 gauge, acoustically treated, solid plate; the other is a perforated 22 gauge sheet. An inert, sound-absorbing material is compressed between the solid plate and perforated steel. The solid exterior is fully primed while the perforated exterior is finished with a durable, epoxy, ivory paint. If desired, the solid exterior may be supplied with a beige, epoxy finish.

When the panels are to be utilized in dust-free areas or exposed to atmospheric vapor such as oil or fluidic particles, or to hihgh humidity, it may be desirable to enclose the sound-absorbing material in a thin-wall, "mosture proof" barrier. Other panel finishes or materials are available for corrosive environments.

When required, forced ventilation and/or air conditioning are sized for enclosure volume and utilization. Please contact your local representative or the factory for application engineering assistance.

| Standard Acoustical Panel Transmission Loss (dB) | ||||||||

|---|---|---|---|---|---|---|---|---|

| 63Hz | 125Hz | 250Hz | 500Hz | 1KHz | 2KHz | 4KHz | 8KHz | |

| Type 1 | 18 | 21 | 28 | 39 | 52 | 53 | 56 | 52 |

| Type 1A | 18 | 21 | 28 | 39 | 52 | 53 | 56 | 52 |

| Type 1C | 20 | 22 | 31 | 41 | 51 | 55 | 53 | 56 |

| Type 2 | 22 | 25 | 31 | 41 | 50 | 54 | 54 | 55 |

| Type 3 | 21 | 23 | 34 | 44 | 50 | 56 | 62 | 60 |

| Type 4 | 24 | 30 | 38 | 47 | 50 | 44 | 49 | 53 |

| Type 5 | 28 | 35 | 47 | 57 | 62 | 65 | 65 | 65 |

| Type 6 | ** | 42 | 53 | 62 | 67 | 70 | 69 | ** |

| Type 7 | ** | 27 | 41 | 52 | 59 | 64 | 67 | ** |

| Type 8 | ** | 21 | 28 | 39 | 52 | 53 | 56 | ** |

| Type 9 | 21 | 19 | 23 | 35 | 50 | 60 | 68 | 72 |

** Denotes ASTM Testing is Not Required at These Frequencies

| Standard Acoustical Panel Absorption – Sabins per sq. ft. | |||||||

|---|---|---|---|---|---|---|---|

| 125Hz | 250Hz | 500Hz | 1KHz | 2KHz | 4KHz | 8KHz | |

| Type 1 | 0.74 | 1.05 | 1.14 | 1.11 | 1.01 | 1.04 | 1.00 |

| Type 1A | 0.56 | 0.79 | 0.86 | 0.83 | 0.76 | 0.78 | 0.75 |

| Type 1B | 0.74 | 1.05 | 1.14 | 1.11 | 1.01 | 1.04 | 1.00 |

| Type 1C | 0.74 | 1.05 | 1.14 | 1.11 | 1.01 | 1.04 | 1.00 |

| Type 2 | 0.74 | 1.05 | 1.14 | 1.11 | 1.01 | 1.04 | 1.00 |

| Type 3 | 0.74 | 1.05 | 1.14 | 1.11 | 1.01 | 1.04 | 1.00 |

| Type 4 | 0.74 | 1.05 | 1.14 | 1.11 | 1.01 | 1.04 | 1.00 |

| Type 5 | 0.74 | 1.05 | 1.14 | 1.11 | 1.01 | 1.04 | 1.00 |

| Type 6 | 1.24 | 1.13 | 1.09 | 1.11 | 1.04 | 0.94 | ** |

| Type 7 | 1.24 | 1.13 | 1.09 | 1.11 | 1.04 | 0.94 | ** |

| Type 8 | 0.30 | 0.70 | 0.90 | 0.99 | 0.90 | 0.80 | ** |

| Type 9 | 0.50 | 0.68 | 1.03 | 1.05 | 1.00 | 0.99 | ** |