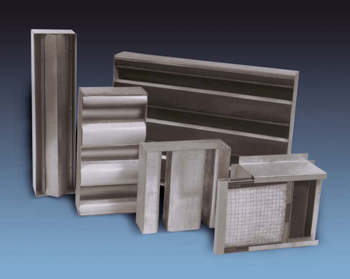

Flatpac (Compact) Attenuators

The Flatpac silencer is a new sound attenuator available in a variety of sizes, depths and configurations.

The Flatpac silencer can silence machine enclosures, openings and forced ventilation.

Applications:

-

Packaged Power/CoGen/EnGen

-

Noise Enclosures

-

Circuit Card Chassis

-

Secured Conference Rooms

-

Fan/Blower/HVAC Systems

-

Control Consoles

-

Electronic Cabinets

-

Hydraulic Power Supplies

-

Cross Talk Silencers

-

Compressors

-

Dust Collectors

-

Heat Pumps

-

Fume Extractors

-

Air Knives/Squeegees

-

Equipment Rooms

-

Transfer Ducts

-

Clean Rooms

-

Motels/Hospitals/Condominiums

-

Modular Office Ventilation

-

Remote Radiators

-

Cooling Towers

Cost Effective/Low Profile/Easy Installation: OEM & Retrofit

Lightweight Flatpacs provide noise attenuation and mobility.

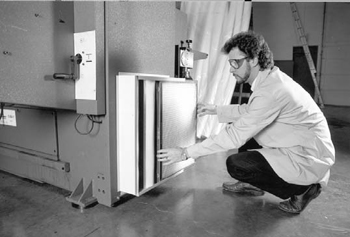

Inexpensively priced for OEM, new construction and retrofit applications, depth of the rugged Flatpac silencer starts at only four (4") inches and may be easily located in dimensionally restricted spaces such as behind ventilation louvers, over enclosure openings and within shallow ducting. In weatherized installations, the Flatpac silencer may be furnished with sealed media, stainless mesh or a reactive design with no media or fibrous materials at all. For decorative purposes, the silencer face may be finished with an attractive grille, louver and/or screen. A wide range of aerodynamic and acoustic criteria may be accommodated within the Flatpac family of silencer configurations.

Flatpacs may be designed for heavy duty applications and specific airflow.

Flatpac silencers may be equipped with an optional air filter to provide an economical, environmental control and silencing system in the same area required by a filter alone. An integral filter/silencer assembly will accept prefilters, intermediate or final filters for air quality and micro contamination control. Noisy control consoles, circuit card chassis and equipment enclosures can be soundproofed and ventilated utilizing the Flatpac silencing system.

Alternatively, complete enclosures may be assembled from Flatpac silencer modules to trap noise internally while providing free air movement around and through the enclosed equipment. Also, the Flatpac silencer may be used in HVAC and heat pump systems, between transfer grilles, behind diffusers and in equipment rooms to reduce undesirable noise.

The Flatpac silencer is available in an infinite variety of sizes. Individual modules may be as small as six (6”) inches square and grow in both length and width to a maximum dimension of forty-eight (48”) inches per side. Modules may be joined to form larger silencer banks as required.

Higher Airflow/More Noise Reduction/Less Pressure Loss

The Flatpac can silence cooling towers and remote radiators while maintaining required airflow.

If a system requires greater performance in insertion loss, higher air flow or velocity and lower pressure losses, then the Alphaloc reactive and/or absorptive silencers are the answer. The Alphaloc series of silencers for fans and blowers will minimize cost, design time, energy consumption and space. Both rectangular and circular silencers are fabricated from proven aerodynamic designs and state-of-the-art materials. For sanitary applications or contaminated gas flows, silencers are available in a reactive design (no fibrous packing). Options include: Stainless Steel, Monel or UHMW construction; clean out/inspection ports; integral C.I.P. system; removable internals; etc. Contact your area representative or the factory direct for selection assistance.

| Selected Model: FS020-18L | ||||||||

|---|---|---|---|---|---|---|---|---|

| Frequency – Hz | 63 | 125 | 250 | 500 | 1000 | 2000 | 4000 | 8000 |

| Insertion Loss – dB | 9 | 11 | 13 | 21 | 30 | 38 | 37 | 36 |

| Pressure Loss – IWG | 0.05 | 0.1 | 0.2 | 0.3 | 0.4 | 0.5 | 0.75 | 1.00 |

| Face Vel. – FPM | 131 | 192 | 272 | 342 | 395 | 441 | 536 | 619 |

| Selected Model: FS040-18L | ||||||||

|---|---|---|---|---|---|---|---|---|

| Frequency – Hz | 63 | 125 | 250 | 500 | 1000 | 2000 | 4000 | 8000 |

| Insertion Loss – dB | 8 | 9 | 10 | 19 | 30 | 33 | 29 | 27 |

| Pressure Loss – IWG | 0.05 | 0.1 | 0.2 | 0.3 | 0.4 | 0.5 | 0.75 | 1.00 |

| Face Vel. – FPM | 318 | 405 | 573 | 690 | 796 | 890 | 1074 | 1240 |