Aeroacoustic Remediation

Telecom Equipment Shelter Application

The History:A major telecommunications company secured an "ideal location" for a cell site. Unfortunately, the proposed site was centered within an urban, residential area. The surrounding community had been established long before the cell site was contemplated, a noise variance was not feasible. To maintain schedule, the cell site construction moved forward with a cautious "wait and see" decision.

Figure 1

The Problem:

Site noise levels were creating community complaints and a threatened legal action! Near proximity of equipment shelter to property line and multi-family dwelling (NAC Class-1 Residential Land Use) did not not provide sufficient acoustical divergence to reduce equipment noise levels. (Reference Figure 1) Added turn-hoods were not only ineffective but actually aggravated the situation both acoustically and aerodynamically. Main source of noise was the enclosed engine generator (EnGen) folowed by the shelter's exterior wall-mountedair conditioning systems.

Figure 2

The Solution:

The site operator contacted us to provide an in situ fix. Drawing on a proprietary data base, we accomplished an aeroacoustic computer simulation of the installation and site topography based on client furnished data.

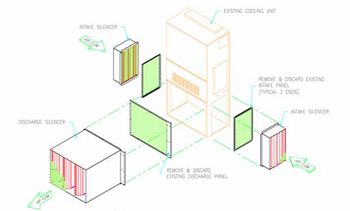

Through rapid computer simulations utilizing inherent acoustic containment features of the shelter construction, we evolved a modular aeroacoustic system, based on empirical test data, which could be quickly installed in the existing openings for EnGen Air Intake and Radiator Discharge. (Reference Figure 2)

Figure 3

Silencer modules may be mounted to the shelter's exterior surfaces, as shown in Figure 1 and Figure 2, totally enclosed within the shelter's interior or divided into any combination of interior and exterior mountings as required (partial penetrations).

Our modular design permits phased implementation, if desired, to assure a cost effective installation. With either a complete or phased installation, we fully guarantee both acoustic and aerodynamicperformance.

Should the HVAC noise also exceed acoustic criteria, a modular sound attenuator system is available that has been aerodynamically sized for each application. Each attenuator system utilizes existing air intake and discharge grille bolt holes for a rapid installation. (Reference Figure 3) The pictured attenuator system will reduce HVACnoise by a nominal 20dBA. More attenuation is available with longer silencers.

Figure 4

The Results:

After installing our modular aeroacoustic system, the client conducted acoustic site tests. The client's e-mail to us stated,

"AWESOME! We can only hear wind noise. It is difficult to get a good reading...lots of ambient noise but it looks like a minimum 25dBA noise reduction!"

The Challenge:

If you have an existing noise problem that requires rehabilitation or are embarking on a proposed project with an acoustic criteria, contact us for assistance starting with a free telephone consultation. From engineering services to noise abatement systems and aerodynamics through system installation, select any or all from our "aeroacoustic supermarket". Just give us a call and let a qualified engineer assist you to establish an effective, guaranteed solution. Tell us about your noisy problems, then let our almost 40 years of experience with noise make your job easier.